In modular infrastructure projects – such as temporary water supply systems, mobile farming containers, or reusable distribution networks – the efficiency and durability of pipeline systems are critical factors. Two aspects must be addressed early in the design process:

The logistical efficiency of pipe supply

The structural intelligence of the connection method

HT pipes (high-temperature drainage pipes) are inherently lightweight but physically bulky. Due to their hollow construction, they consist of more than 95% air by volume. For example:

A 40-foot shipping container holds ~500 linear meters of 110 mm HT pipe

Net transport volume: ~5.3 m³ of pipe, but the container occupies over 55–60 m³ of space

Even modest distances – beyond 300 km – result in transportation costs exceeding the actual value of the materials. The issue becomes worse with special parts (bends, junctions), which increase complexity, storage needs, and procurement risk.

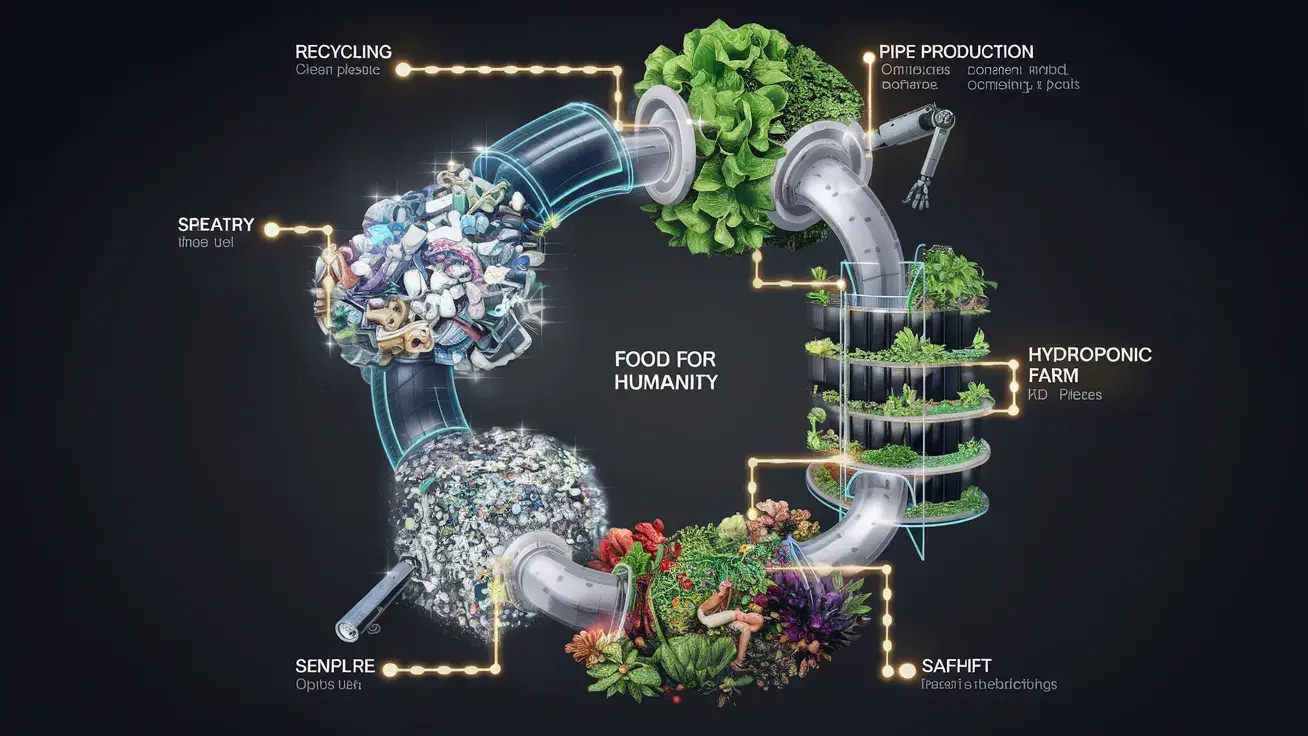

Instead of transporting pipe volume, it is significantly more efficient to deploy a compact on-site manufacturing unit:

Plastic granulate (new or recycled) is processed directly at the construction site

Pipe sections and connectors are produced on demand via extrusion or 3D printing

The production module fits into a container or trailer and is fully mobile

Advantages:

Real-time geometry adaptation

Easy deployment across sequential project sites ("build once – use anywhere")

Beyond the pipe itself, the connection system plays a key role in system longevity and reliability. Common glued pipe systems without sealing rings may be suitable for indoor use or short fixed runs – but are fundamentally unsuitable for long, outdoor or modular applications.

Plastic pipes are subject to thermal expansion. For polypropylene (PP) – a standard material for HT pipes – the coefficient of linear expansion is:

≈ 0.15 mm per meter per Kelvin

Example calculation:

Pipe length: 80 m

Temperature variation: ΔT = 25 K (day/night or seasonal)

→ ΔL = 80 m × 0.15 mm/m/K × 25 K = 300 mm (30 cm)

In glued systems, this expansion leads to high internal stress, risking cracks, leaks, and material fatigue.

Male/female sockets with sealing rings allow axial pipe movement inside the joint

Thermal expansion is compensated within the connection

System remains watertight and stress-free even under fluctuating conditions

Additional benefits:

Tool-free assembly, no curing time

Easy disassembly or repair

Vibration and ground-movement resistant

Fully compatible with on-site produced fittings

A resilient, modular pipeline system must follow two core principles:

Produce where you build – not where the truck starts

Let materials move where movement is natural

Transporting HT pipes is transporting air.

Producing them on-site – and using flexible, pressure-relieving connections –

means saving resources, extending lifespan, and enabling truly sustainable infrastructure.

*Flying fields and complete planets will be come with a extra fee.